![]() 服务热线:+86 138 1668 1782

服务热线:+86 138 1668 1782

![]() 公司地址:上海市青浦区外青松公路4568号 No.4568, Waigingsong Road, Qingpu District, Shanghai, China

公司地址:上海市青浦区外青松公路4568号 No.4568, Waigingsong Road, Qingpu District, Shanghai, China

![]() 联系邮箱:guijue@guijue.net

联系邮箱:guijue@guijue.net

![]() 联系人:桂先生

联系人:桂先生

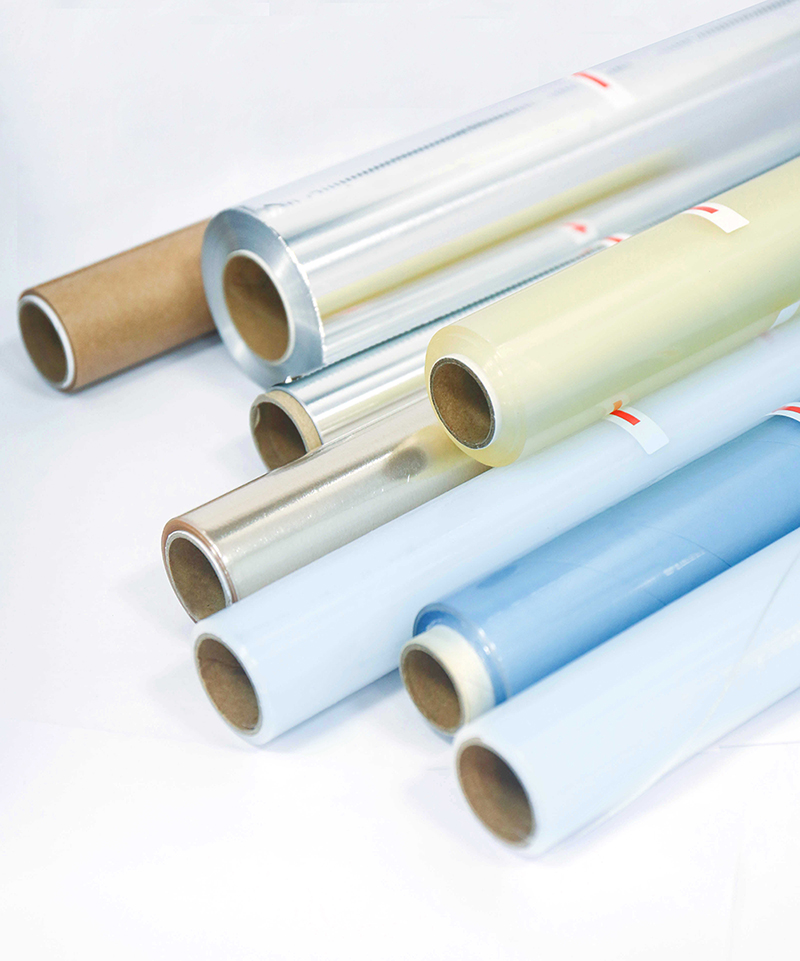

全自动保鲜膜复卷机GJ-CF01为我司针对目前保鲜膜市场需求推出的新一代保鲜膜复卷机。相较于其他同类机型,本设备具备自动贴短标、反折贴短标、反搓及点断等全新功能,处于国际领先地位。我司是唯一一家拥有反折贴短标专利的生产商,也是唯一一家将点断功能每一段公差控制在±2毫米的复卷机制造商;与此同时,这款设备的反搓功能可以实现百分之百的成功率,反搓工艺紧致平直,非常完美。以上功能将为客户实现高端质量生产的自动化和无人化奠定良好的基础,大大节约人力与材料成本。

精良的零部件和加工工艺,配上伺服和步进控制系统的升级换代,进一步实现了复卷长度和贴短标的高精度。人机界面全自动控制,操作更人性、更便捷。在放料和卷膜机构配置不同的伺服电机,卷膜张力更稳定;不仅可复卷吹膜和流延膜,同时还能保证在点断过程中不会出现拉断现象,设备稳定性更高。

不停机自动贴短标:贴标位置准确,节省人力和材料成本

反折贴短标:启封更便捷,节省成本

点断:每段可实现 ±2毫米的公差

反搓:100%自动搓卷,可助力客户实现全自动生产,节省人力成本(可根据客户要求搓成三角形)

全自动换母卷膜:国内首创功能,无需穿膜,效率更高

伺服控制系统:张力控制更稳定,成品品质更好,收卷长度更精准

无母卷料、无纸管、断膜、膜上钢辊等自动停机报警功能

技术参数

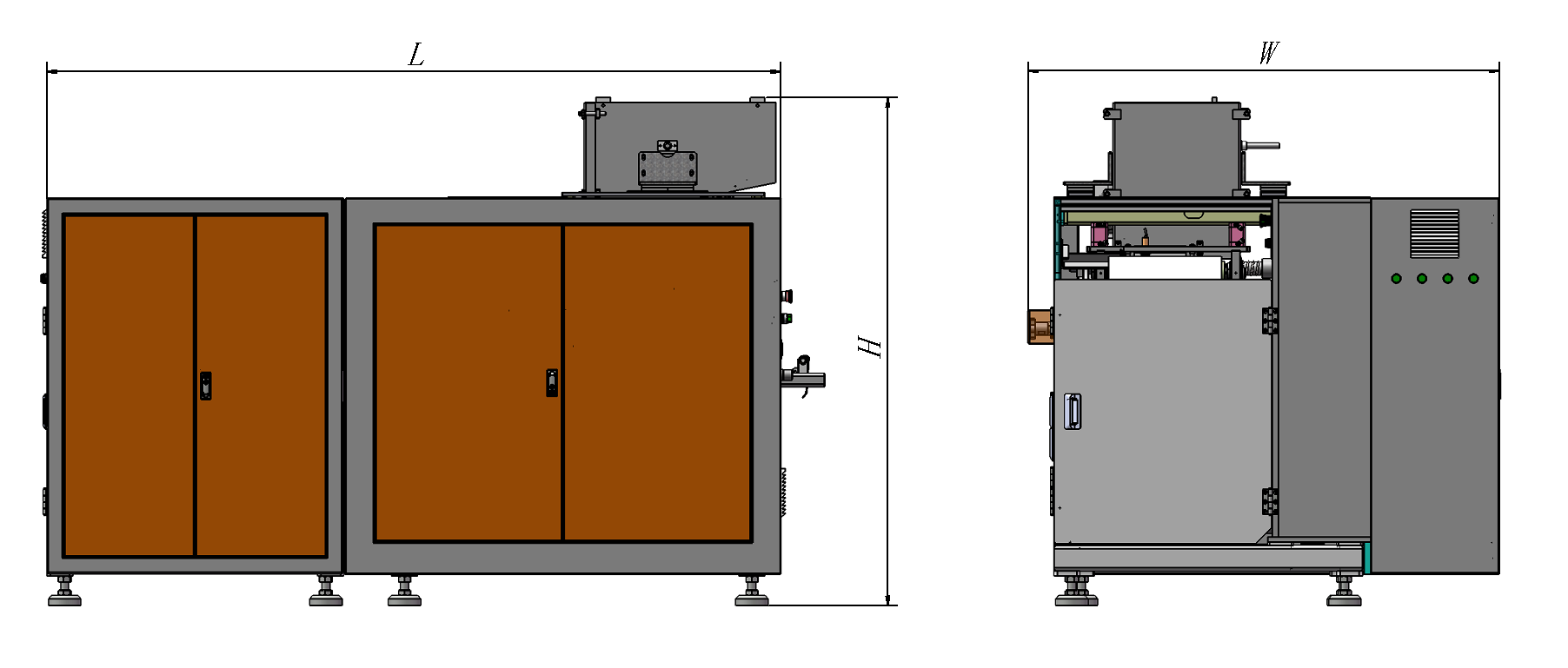

1) 设备尺寸:2282 * 1465 * 1581 mm

2) 总功率:6.5KW

3) 电源:三相 380V

4) 线速度:700m/min

5) 母卷宽度:220 - 330mm

6) 产品规格:30m - 500m/roll

7) 设备产能:8 - 10 roll/min(30m/roll)或 5 - 7 roll/min(60m-100m/roll)

8) 短标尺寸:最小尺寸10*20mm

Machine model: GJ-CF01

Automatic Cling Film Rewinding Machine: This device is a new generation of cling film rewinding machine in response to the current market demand for cling film. Compared with other similar devices, this machine has new functions such as automatic short-labelling, reverse folding & short-labelling, reverse rubbing, and perforating, reaching the world’s leading position. Our company is the only manufacturer with a patent for reverse folding and short labelling, and also the only one that controls the tolerance of each section of perforating to ±2 mm; the reverse rubbing function can achieve a 100% success rate in a tight and straight way. The above functions will lay a good foundation for customers to realize high-end quality production automation and unmanned operation, greatly saving labor and material costs.

Sophisticated parts and processing technology, coupled with the upgrade of servo and stepper control systems, further promote high precision of rewinding length and short-labelling. The human-machine interface is fully automatic, making the operation more humane and convenient. Different servo motors are configured in the unwinding and rolling film mechanisms. The tension of the rolling film is adjusted by the servo motor, which can not only rewind the blown film and cast film, but also ensure that there will be no breakage when perforating the film, ensuring higher production stability.

Automatically apply short-labeling without stopping the machine: More accurate labeling position, labor and material cost saving

Reverse folding & short-labeling: More convenient opening and cost saving

Perforating unit: The material count is more accurate with a tolerance of ±2 mm for each finished roll

Reverse rubbing: 100% automatic rubbing at the end of each finished roll, which can help customers achieve automatic production and save labor costs (can be rolled into triangles according to customer requirements)

Fully automatic film changing of jumbo roll: The first in China, and there is no need to manually pull the cling film onto the roller, improving efficiency

Servo control system: Tension control is more stable, and winding length of finished rolls is more accurate

Automatic shutdown alarm function for no jumbo roll material, no paper tube, film breakage, steel roller on film, etc.

Technical Parameters:

1) Equipment size: 2282 * 1465 * 1581 mm mm

2) Total power: 6.5KW

3) Power supply: three-phase 380V

4) Linear speed: 700m/min

5) Jumbo roll width: 220 - 330mm

6) Product specifications: 30m - 500 m/roll

7) Equipment capacity: 8 - 10 roll/min (30m/roll) or 5 - 7 roll/min (60m-100m/roll)

8) Short label size: minimum size 10*20mm